Introduction to concrete building products

Practical Action

Both methods of prestressing rely on the use of expensive

equipment and are not suitable for small-scale operation. It

should also be noted that it is more difficult and less safe to

demolish a building containing pre-stressed concrete elements

than one incorporating conventional reinforced concrete.

Decorative Products

These comprise garden ornaments and statuettes, benches

and seats and balustrades for staircases, for example. They

are usually made with a mix rich in cement that is made

flowing by the addition of excess water or the use of

superplasticizers. The maximum aggregate size may be

limited, e.g. to one centimetre across for larger products and

half a centimetre, or less for smaller and more decorative

products.

Colouring or staining of the concrete may be used to achieve

the decorative effects. They can also be painted, although

most paints do not hold fast well on concrete, especially

outdoors.

The concrete is usually poured into plastic or stiff rubber

moulds that have been specially fabricated for the products.

These can incorporate quite intricate shapes. When the

concrete has hardened the plastic moulds are simply prised

open while rubber moulds can be peeled off. It is especially

important to keep these moulds clean between uses and to

discard them when they start to deform with usage.

Large-scale Components

Large prefabricated concrete products are usually made at

large factories that use large specialised moulding, handling

and transport equipment. Products include wall panels,

staircases and even whole sections of buildings that are

subsequently bolted together at the building site.

In Europe and North America prefabrication was common for

building, especially for mass housing, several decades ago.

However, technical problems have been found with significant

amounts of this construction leading to the need for

demolition in some cases. Quality control at large-scale

prefabrication works then needs to be exceptionally high.

Steel reinforcement is used in nearly all large-scale

prefabricated components. This may also be pre-stressed.

Experimental and practical studies have also been

undertaken on prefabricated building components of

ferrocement. Ferrocement is a type of reinforced concrete

that uses one or more layers of thin steel wire mesh, e.g.

chicken wire, as reinforcement instead of conventional steel

rods, ties and cages. It is therefore cheaper than

conventional reinforced concrete and more orientated

towards the conventional builder rather than more highly

engineered construction.

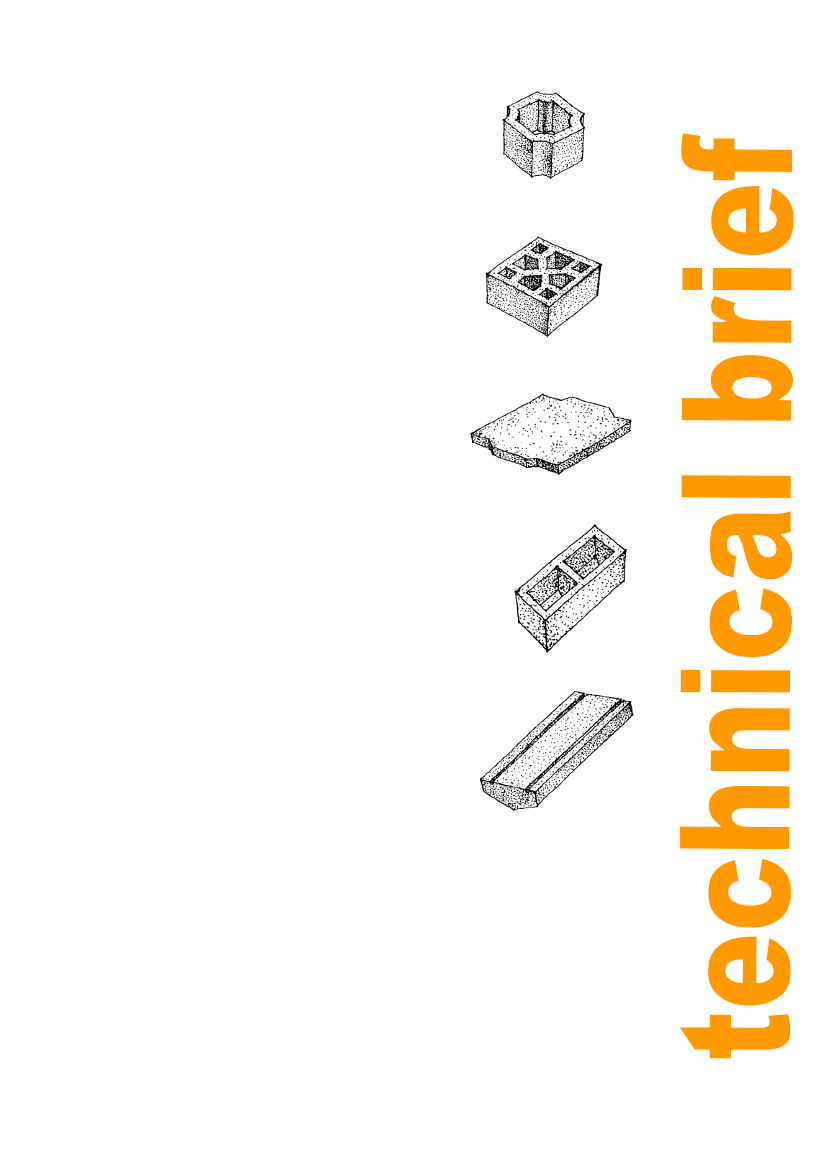

Figure 2: Selection of Concrete

Products (page 30) – No. 1 Simple

air brick (as made in Kenya), No. 2

More complex example of air brick,

No. 3 Floor tile, No. 4 Hollow

block, No. 5 Wall coping.

Illustration from Vibrated Concrete Products

Production Manual (Draft), by Amon

Ng’ang’a, Building Materials and Shelter

Programme of IT Kenya, October 1994.

Prefabricated ferrocement wall and roof panels have been

7